Our leadership in this field with our heat tracing applications in a large industrial areas is unquestionable.. These applications have create our standards.

- General Details

- Contact Form

- Comments

Freeze Prevention in Pipelines with Heating Cables

Temperature Protection and Freezing Prevention in Pipelines

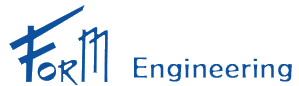

The using of electrical heating cables for heating and heat tracing systems is increasing day by day in industrial facilities. Electric heating cables ınstallation cost and simplify of use are more convenient than the steam and hot water systems used in the past. This is due to the reliability and very long life provided by modern heating cables. The flexibility and different strengths of the heating cables provide energy efficiency and simplify of control in industrial applications. Heating cables can be connect to advanced control systems and the line temperature can be controlled instantly. There is a heating cable convenient for all kinds of difficult conditions for different insulation structures. Heating cables don’t have a corrosion and maintence cost so operating costs are low. With time, it does not require maintenance or repair, such as steam and hot water lines.

With the developing technology today, heating cable systems with low installation costs are used in all kinds of industrial areas with automation controls. The most common using heating cable applications prevent the pipe lines freezing from the installed facilities in cold climates. Heat trace system materials are called as heater cable, cable resistance or heating tape.

Pipeline Heating

Over the past thirty years, the using of electrical heating cables for heating and heat tracing in industrial facility has been increasing compared to steam and hot water systems. This is due to the reliability and very long life provided by modern heating cables. In addition, electrical energy can be controlled very easily and the heating cables do not require maintenance, provides great savings in operating costs.

Pipeline Heating

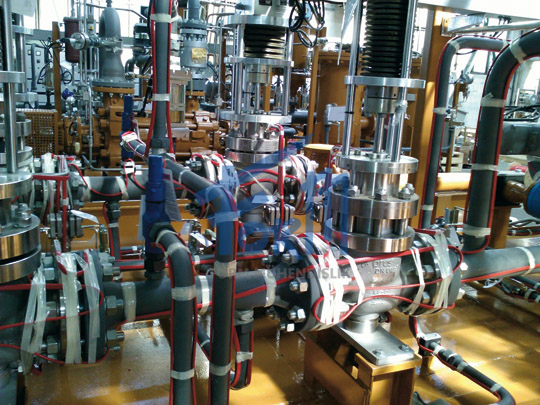

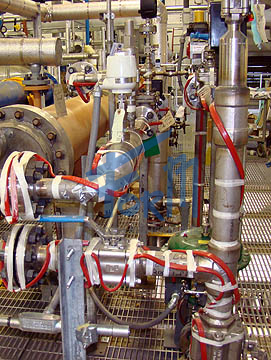

For example, freezing protection of gas, liquid and viscous fluids, heat loss prevention or heating need common demand in industry. In any environment and process, electric heaters can solve problems with high reliability and ptactice. Because of the low installation cost, any product in this type of system can be pump and maintain keep fluency with heating cables. Measurement devices such as pumps, valves, filters and transmitters are prevented from blocked. As a result, industrial facilities have the opportunity to work without interruption.

Pipeline Heating

Process measuring devices located outside are protected using a heater cable. Measurement values are controlled correctly and production is not damaged. Please consult us for technical information with heating cable. There are many types of heating cables and they differ in insulation, strength and structure. Different heating cables are used for each project and area.

Pipeline Heating

Pipeline Heating

As Form Engineering, we have been implementing so many projects since 1992. we provided uninterrupted service of industrial facilities. We are proud to be the preferred company in industrial facilities with our strong references and personel.

Pipeline Heating

Deneme